ATEX - equipment for potentially explosive atmospheres

Equipment and protection systems in potentially explosive atmospheres must be safe. The manufacturer of equipment and protections systems used in potentially explosive atmospheres is responsible for ensuring that the equipment or protection system meets the requirements laid down in the Directive on ATEX equipment.

The Directive on ATEX equipment regulates the safety of equipment and protection systems for potentially explosive atmospheres. ATEX comes from the French words “atmosphères explosibles”.

The purpose of the Directive on ATEX equipment is to ensure that ATEX products in use and on the market are safe for persons, domestic animals and property. ATEX products must be safe in their intended purpose of use and anticipated disruptions, and their structure must not allow explosive mixtures of air to ignite.

What are potentially explosive atmospheres?

Potentially explosive atmospheres are conditions that potentially contain an explosive mixture of air. The potentially explosive mixture of air may be caused by flammable gases, mists, vapours or dust when mixed with air.

Potentially explosive atmospheres primarily occur when handling flammable liquids and gases, and dusts, in the processing industry and distribution substations, for example.

Scope of application of the Directive on ATEX equipment

The Directive on ATEX equipment applies to equipment intended for use in potentially explosive atmospheres, including

- electrical and mechanical equipment with an ignition source;

- protective systems;

- components of equipment and protective systems;

The scope of application also includes safety, regulating and control equipment that is intended for use outside the potentially explosive atmospheres but is necessary for the safe operation of equipment and protection systems or that reduces the risk of explosion.

The scope of application of the Directive on ATEX equipment excludes

- medical devices;

- means of transport;

- seagoing vessels;

- personal protective equipment;

- equipment and protective systems where the explosion hazard results from the presence of explosive substances or unstable chemical substances;

- equipment intended for use in domestic and non-commercial environments where potentially explosive atmospheres may only rarely be created, solely as a result of the accidental leakage of fuel gas;

- simple equipment and equipment whose sole potential source of ignition is static electricity caused by the process;

Classification of products

The manufacturer must define the ATEX equipment’s group and category based in its purpose of use.

The Directive divides equipment into two groups based on where the equipment is used:

- group I products are intended for use in the underground parts of mines and in those parts of surface installations of such mines that are likely to become endangered by firedamp and/or combustible dust;

- group II products are intended for use in other environments that are likely to become endangered by explosive atmospheres.

The groups are divided into equipment categories. Products in group I are divided into two equipment categories: M1 and M2 and products in group II are divided into three equipment categories: 1, 2 and 3. For group I, one of the factors that the categorisation is based on is whether the product becomes de-energised in the event of an explosive atmosphere. Products in group II are categorised based on where the product’s intended place of use is, i.e. is the atmosphere always potentially explosive or is it likely to occur for short or extended periods. Further information on the categorisation of products is available in Annex I of the Directive on ETAX equipment.

Safety, regulating and control equipment is categorised based on the equipment or protection system for the operation of which they are necessary and to the operation of which they contribute.

| Level of protection | Group I | Group II | Efficiency of protection | Operating conditions |

| Very high | M1 | Two independent means of protection or protection assured in the event of two faults occurring independently of each other. | The equipment remains energised and operational in an explosive atmosphere. | |

| Very high | 1 | Two independent means of protection or protection assured in the event of two faults occurring independently of each other. | The equipment remains energised and operational in atmosphere categories 0,1,2 (G) and/or 20,21,22 (D) | |

| High | M2 | Normal operation and severe operating conditions | The equipment de-energises in the event of an explosive atmosphere | |

| High | 2 | Normal operation and anticipated frequently occurring disturbances or equipment faults. | The equipment remains energised and operational in atmosphere categories 1,2 (G) and/or 21,22 (D) | |

| Normal | 3 | Normal operation | The equipment remains energised and operational in atmosphere categories 2 (G) and/or 22 (D) |

Obligations of the manufacturer, importer and seller

In addition to product requirements, the Directive on ATEX equipment creates a number of obligations for the manufacturer, importer and seller of the product.

How to ensure conformity of an ATEX product

Annex II of the Directive on ATEX equipment defines the essential safety and health requirements. The manufacturer can demonstrate compliance by testing the product in accordance with harmonised standards.

In addition to the safety level required of the equipment, the equipment category determines what conformity assessment procedure the manufacturer must apply. Conformity assessment procedures are described in Annexes III - IX of the Directive on ATEX equipment.

The manufacturer must check and test that the product complies with the requirements of the Directive on ATEX equipment in accordance with the conformity assessment procedures. The manufacturer must also assess the risks presented by the product.

| Equipment category | Conformity assessment procedure |

| 1, M1 and protective systems | EU-type examination, module B + |

| 2 and M2 electrical equipment and combustion engines |

EU-type examination, module B + - Product quality assurance, module E Unit-based verification, module G |

| Other equipment | Internal production control, module A + documents to a notified body Unit-based verification, module G |

| 3 | internal production control, module A Unit-based verification, module G |

Whether a third party, a Notified Body, needs to be involved in assessing the conformity of a product depends on the conformity assessment procedure used by the manufacturer. If a notified body is involved in the production control stage, the identification number of the notified body is appended to the CE marking.

The manufacturer must draw up technical documentation for the product. It must be possible to assess the product’s conformity with applicable requirements based on the technical documentation. The documentation must include an appropriate analysis and assessment of the risks.

In addition to the technical documentation, an EU Declaration of Conformity must also be drawn up. The EU Declaration of Conformity must be delivered to end users with each product. An EU Declaration of Conformity is not drawn up for components. Instead, a manufacturer's declaration of conformity is required. The manufacturer's declaration of conformity of components must also be delivered to end users with each component.

The manufacturer must also draw up instructions and information necessary for the safe and purposeful installation, operation and maintenance of the product. For example, when the product is repaired, no changes may be made to the product’s explosion protection structure. If necessary, the manufacturer may require that any service of and repairs to the product may only be performed by the manufacturer or its authorised representative.

The manufacturer must attach a CE marking to the product before it is placed on the market or taken into use. Requirements pertaining to CE marking are not applied to components.

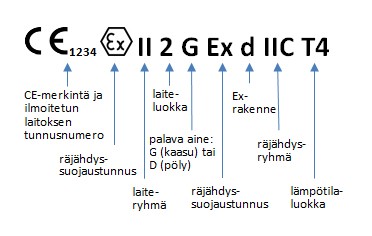

In addition to the CE marking, products must also include other markings required by the Directive, such as traceability requirements, year of manufacture and the special marking for explosion protection, including the Ex symbol and markings indicating the equipment’s group, equipment category and intended operating environment. Furthermore, they must also be marked with all information essential to their safe use.

Image: ATEX equipment CE marking and special marking for explosion protection.

CE1234

CE marking and ID number of notified body

Ex

explosion protection symbol

II

equipment group

2

equipment category

G

explosive substance: G (gas) or D (dust)

Ex

explosion protection symbol

d

Ex construction

IIC

explosion group

T4

temperature class