Conformity of tanks and packaging used for transporting dangerous goods

Packaging and tanks must meet the relevant requirements. The manufacturer, importer, etc., of the tank or packaging must be able to demonstrate that the tank or packaging is made, designed and verified in accordance with the relevant decreed and prescribed requirements. Conformity is indicated by an approval marking in the sign on the tank or packaging. The tank and packaging approvals are issued by TDG inspection bodies.

Packaging

The structure type of each packaging must be tested using a method approved by a TDG inspection body. The structure type of the packaging must be approved by a TDG inspection body. Before the structure type is adopted, it must pass the specified type tests. The type tests must be re-performed if there are any changes in the structure type, material or manufacturing method of the packaging.

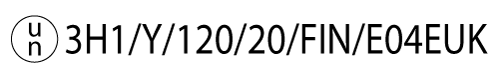

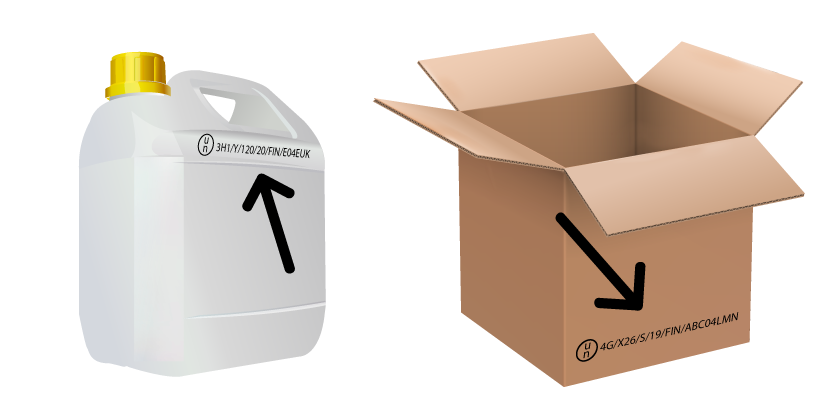

See the image for a packaging approval marking.

The approval marking of UN type-approved packaging includes, e.g. the UN packaging ID, packaging type identifiers, test information and the year of manufacture.

|

4G/Y145/S/02/ |

Means: |

For the requirements applicable to the manufacture and approval of packaging, see section 6.1 of the Appendix to the Finnish Transport and Communications Agency on the Transport of Dangerous Goods by Road.

See the image for examples of a canister, a cardboard box and their approval markings.

IBC packaging

The structure, equipment, tests and markings of IBC (Intermediate Bulk Container) packaging must be approved and tested by a TDG inspection body.

IBC requirements:

- A permanent marking indicating the production material, purpose of use and time of production

- Type testing of the packaging

- Approval certificate for each approved structure type

- A conformity marking

- Inspections every 2.5 and 5 years performed by a periodic TDG inspection body or TDG inspection body

- The maximum life of plastic packaging is 5 years

The basic IBC type approval marking formula:

|

11A/Y/02 99/ |

Means: |

For the requirements applicable to the manufacture, testing and inspection of IBC, see section 6.5 of the Appendix to the Finnish Transport and Communications Agency on the Transport of Dangerous Goods by Road.

See the image for an example of IBC packaging and the approval marking.

Periodical IBC inspections

IBC packaging must be inspected every 2.5 and 5 years. In addition, a separate inspection must always be performed following maintenance or repair. Pre-commissioning inspections, periodical inspections and additional inspections are conducted by a Tukes-approved TDG inspection body or periodic TDG inspection body. The different IBC inspections are performed to the extent indicated in the table below.

Inspection methods |

Before commissioning |

Every 5 years |

Every 2.5 years |

Following repair |

|---|---|---|---|---|

Correlation with the approved structure type, including the marking |

X |

X |

- |

X |

Internal condition |

X |

X |

- |

X |

External condition * |

X |

X |

X |

X |

Proper functioning of operating equipment |

X |

X |

X |

X |

Leak test ** |

X |

X |

X |

X |

* The leak test must be performed on metal, stiff plastic or compound IBC packaging meant for liquids, or solids and filled or emptied using pressure.

** Any thermal insulation on IBC packaging must be removed to the degree necessary in order to inspect the body.

Tanks on vehicles

Tanks on vehicles must be designed in such a way that they can withstand the stress resulting from the content and transport.

Vehicle tank requirements

- Tanks on vehicles must be manufactured, tested and inspected pursuant to the relevant standards.

- Tanks on vehicles must be made from a suitable material resistant to temperatures between -40 ̊C and + 50 ̊C.

- Welded joints and the inspections thereof must always be performed in accordance with the requirements.

- Each tank must be approved by a TDG inspection body.

- Tanks on vehicles must be inspected before commissioning and periodically inspected at specific intervals.

- Each tank must be equipped with a marking sign indicating, e.g. the approval number, production year, total capacity, tank code, Tukes registration number as well as the information of the inspection body performing the inspections and the time of the inspection.

- For class 2, gases, the approvals are performed by the notified inspection body.

For the standards applicable to the manufacture, testing and inspection of tanks, see section 6.8 of the Appendix to the Finnish Transport and Communications Agency on the Transport of Dangerous Goods by Road.

The competitive authority for radioactive materials is the Radiation and Nuclear Safety Authority.

The technical details, approval and inspection information of the TDG tank are provided on the container sign.

See the image for an example of a TDG sign on a tank.

Approval and inspections of tanks and packaging

- Class 1, 3–6, 8 & 9: Explosives, flammable liquids, etc.

- TDG inspection body:

- Approval of tanks and packaging

- Periodic tank inspections

- Periodic IBC packaging inspections

- Bulk container approvals

- Periodic TDG inspection bodies:

- Periodic IBC packaging inspections

- TDG inspection body:

- Class 2: Gases

- Notified type A inspection body:

- Approval of gas tanks

- Periodic gas tank inspections

- Approval of gas cylinders and vessels

- Periodic inspections of gas cylinders and vessels

- Notified type B inspection body:

- Periodic inspections of gas cylinders and vessels

- Notified type A inspection body:

- Class 7: Radioactive materials

- Radiation and Nuclear Safety Authority

- Approval of tanks and packaging

- Periodic tank and packaging inspections

- Radiation and Nuclear Safety Authority

Obligation to register tanks and pressure vessels

In Finland, over 450-litre tanks or pressure vessels intended for the transport of dangerous goods must be registered in the equipment register of Tukes. In the new Act on the Transport of Dangerous Goods (entry into force on 1 September 2023), the registration of tanks has been extended to apply to non-pressurised tanks. The registration does not apply to IBC because it is packaging. The owner or possessor of the tank or pressure vessel registered in Finland must report it to the inspection body, which will register it in the equipment register of Tukes. The inspection body will provide the tank with an individual register number in “T-1234” format marked on the container sign. Registration of the tanks subject to the registration obligation in accordance with the new law takes place in connection with the next check.