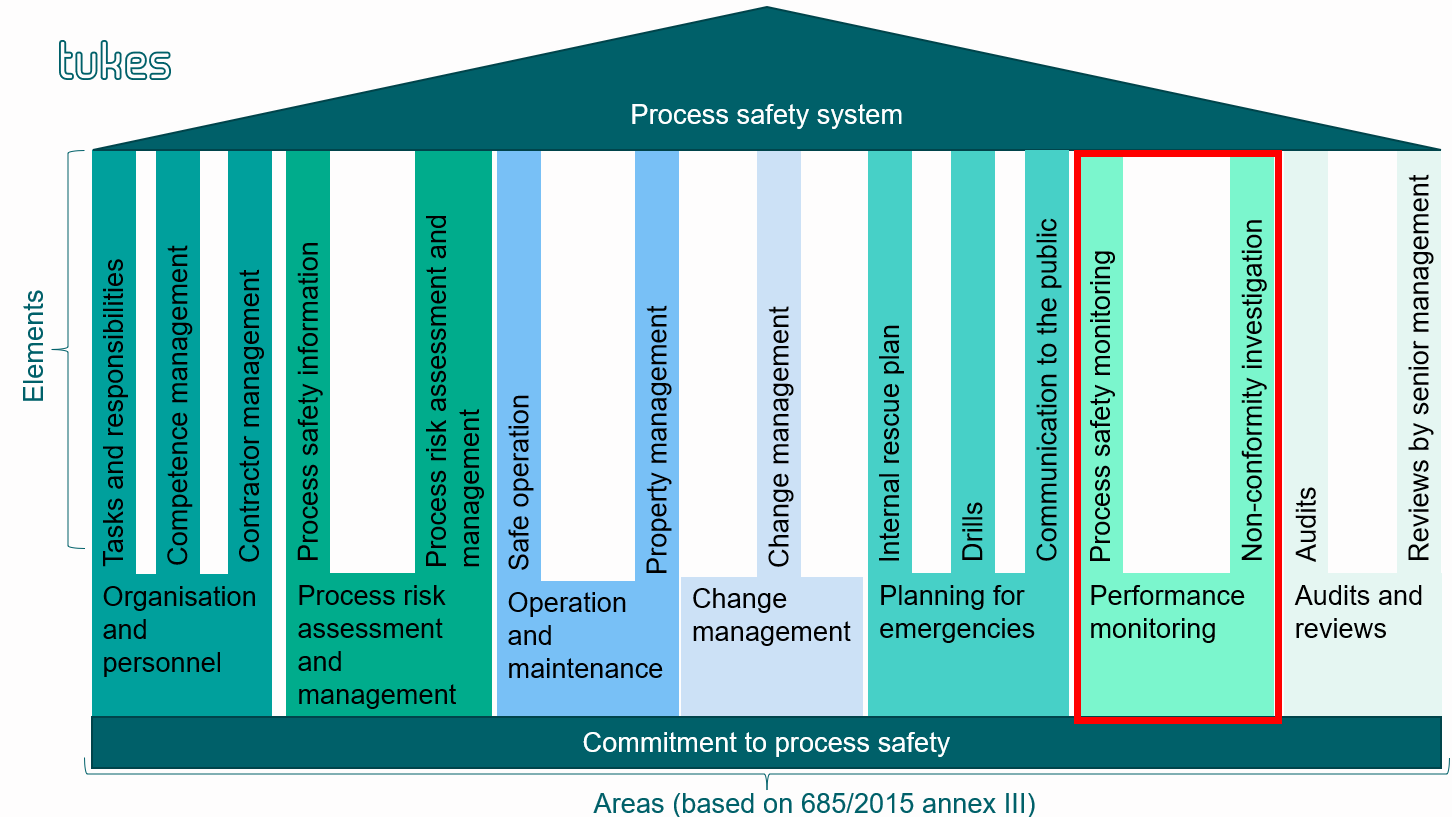

Performance monitoring

‘Performance monitoring’ is an area of the process safety system consisting of two elements: process safety monitoring; and non-conformity investigation.

Performance monitoring should focus on process safety. Any non-conformities and monitoring procedures related to process safety should be separated from procedures related to occupational safety.

Identifying how the state of process safety can be monitored and assessed in plant operations in concrete terms is key in process safety monitoring. Once an effective procedure has been defined, it serves to monitor the state and development of process safety.

The ground rule of non-conformity investigation is that process safety non-conformities have been defined (what is part of normal activities and what is a non-conformity). Identifying the root causes of non-conformities is key in non-conformity investigations. The recurrence of non-conformities can be prevented by affecting their root causes.

Non-conformity investigation

Requirement

Economic operators must define what process safety non-conformities mean. Non-conformities must be classified in accordance with this definition.

Approved procedure

The definition of process safety non-conformities takes into account Tukes guidelines such as the guide for process safety and its measurement.

The economic operator also addresses thresholds for reporting to various authorities in the classification of non-conformities (either independently defined thresholds or those defined based on official guidelines).

The accident reporting practices of Tukes are presented on the Tukes website.

Requirement

Economic operators must have a procedure in place to collect process safety non-conformity reports.

Approved procedure

Plant employees and subcontractors can report any observed process safety non-conformities and near-miss incidents. Those who report their observations are notified of the processing of their report and the measures defined as a result of it.

Requirement

Economic operators must have a documented procedure to investigate process safety non-conformities.

Approved procedure

The investigation procedure is selected based on the non-conformity type, the severity of consequences or potential consequences.

Instructions for non-conformity investigations include the selection of the non-conformity investigation procedure.

Requirement

Economic operators must maintain records of non-conformities, the corrective measures defined for them and the implementation of the corrective measures. Cases must be closed after the completion of measures.

Approved procedure

An economic operator maintains records that indicate non-conformities, root causes, corrective measures and responsible persons as well as acknowledgements of the implementation and monitoring of the measures taken.

Such records can be maintained in an electronic non-conformity system.

Requirement

Economic operators must define who are responsible for non-conformity investigations. Those responsible for non-conformity investigations must have sufficient competence.

Approved procedure

An economic operator designates a person responsible for non-conformity investigations and participants in them. Another good policy is to record competence/training requirements for non-conformity investigations, based on which competence can be assessed.

Process safety monitoring

Requirement

Economic operators must have a documented procedure to monitor process safety.

Approved procedure

The procedure describes how process safety monitoring information is collected and processed and who is responsible for these steps. The procedure also describes how frequently information is collected and processed, how observations are communicated, and how the implementation of the measures required based on observations is monitored.

Observations related to the state of process safety are communicated to a sufficient extent in the location: to the location’s managers/responsible persons at minimum, and also to the personnel if required.

Process safety monitoring is especially targeted at processes in which chemicals presenting a major accident hazard are handled.

Process safety monitoring and related metrics focus on the process safety system and risk management measures.

Tukes has prepared a guide for measuring process safety.

Requirement

Economic operators must carry out regular documented observation rounds for process safety.

Approved procedure

The rounds cover areas for process safety, including pipeline brackets, earthing wires, the barrier condition, labelling, etc.

The observation rounds can also include interaction with operators and others working in the areas.