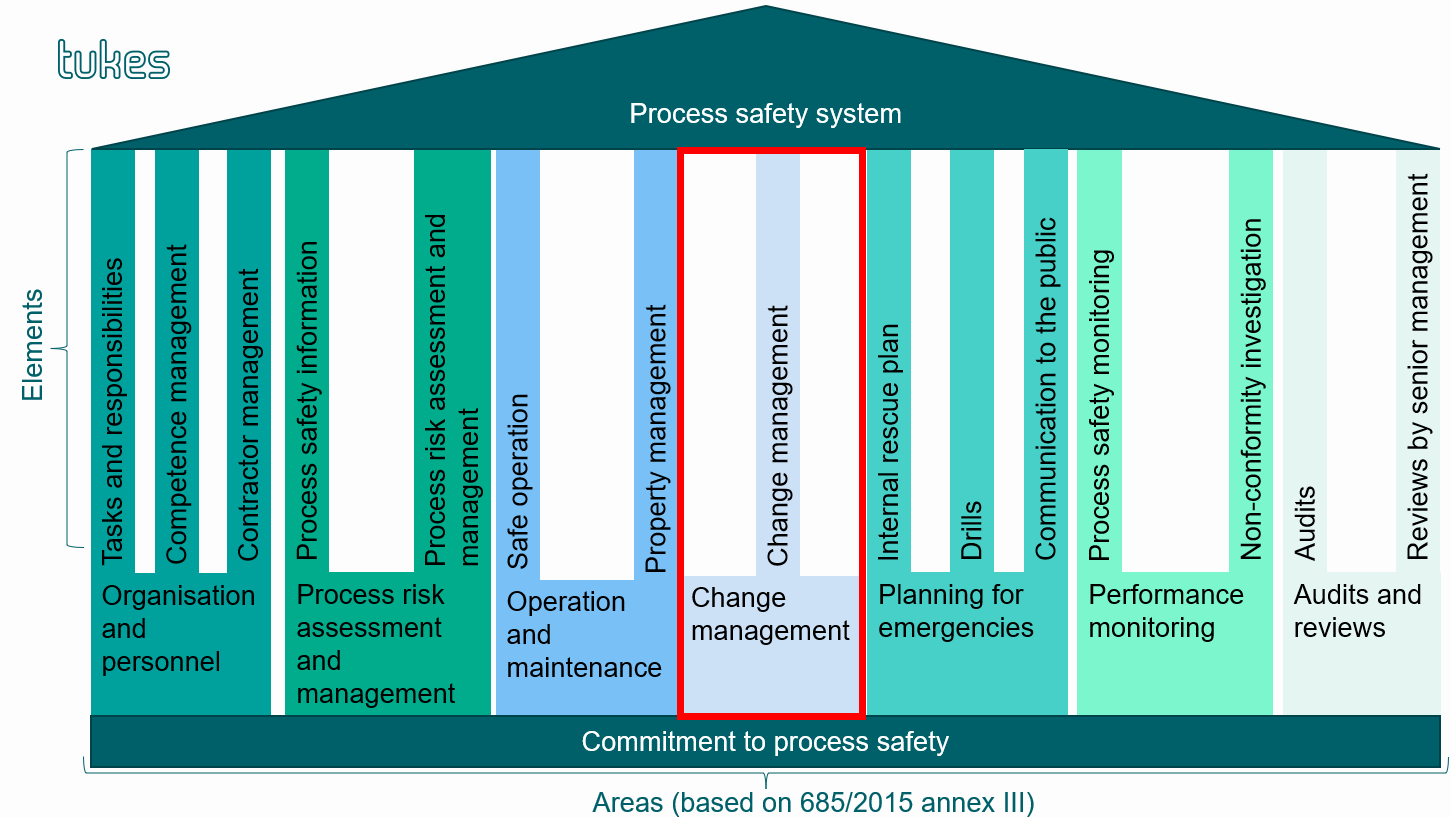

Change management

‘Change management’ is an area of the process safety system consisting of a single element: change management.

Change management is a systematic work process which covers identifying changes, assessing risks, verifying compliance with requirements, and the planning, implementation, safe deployment and closing of changes.

Changes may be related to equipment, processes, software or personnel. The goal of change management is to ensure that changes are made under control while addressing process safety.

Change management helps clearly define the responsibilities and tasks related to changes, including communication, training and the updating of the plant’s documentation.

CHANGE MANAGEMENT PROCEDURES

Requirement

Economic operators must have a documented procedure in place for change management. Hazardous chemicals and process safety must be taken into account in change management procedures.

Approved procedure

An economic operator can present a written change management document, in which the economic operator describes all the procedures related to change management. The change management procedure includes the following: identifying changes, assessing risks related to changes and defining control measures for them, change planning (implementation method and schedule), a testing and verification plan for changes, deployment and training as well as monitoring and documentation. The change management procedure is part of internal auditing.

Requirement

Economic operators must have a procedure in place to identify any changes in operations that affect process safety.

Approved procedure

An economic operator’s written change management instructions identify typical changes and related procedures. Different types of changes include changes in chemical pipelines and equipment, process changes, software changes, organisational changes, changes in maintenance and operations, changes requiring a notification for the authorities, and other changes affecting process safety. The change management procedure addresses typical incidents at the plant and subsequent repairs. The identification and assessment of changes is based on process safety information and the plant’s risks. The change management process does not depend on funds allocated to changes, for example.

Requirement

Change management procedures must be audited regularly and developed based on findings.

Approved procedure

The change management procedure is within the scope of internal auditing. Audits focus on the effectiveness of the change management process.

CLASSIFYING CHANGES AND SELECTING THE PROCEDURE

Requirement

The procedures used to assess and address the impact of changes in chemical information (classification and quantities) must be described in the change management process.

Approved procedure

Changes in chemical information are monitored. If there are any significant changes, the economic operator contacts the plant’s responsible supervisor at Tukes who assesses the need for further measures (change notification, change permit, processing during the next periodic inspection). Examples of significant changes are available on the Tukes website. If there are significant changes in chemical information, a change notification must be submitted to Tukes to verify the number of chemical permits and/or the scope of operations. In conjunction with further measures, the economic operators makes the changes required in the plant’s list of chemicals maintained in the KemiDigi system.

Requirement

Economic operators must have a procedure in place to apply for change permits and notifications from Tukes.

Approved procedure

The procedure describes the roles and responsibilities required to identify the need for change notifications, and if required, to prepare change notifications for Tukes.

Requirement

The role and responsibility of the chemicals and LPG supervisor in the change management process must be defined and described in writing.

Approved procedure

Change management procedures identify the role of the chemicals/LPG supervisor as part of the change management process. If required, the operations supervisor can authorise others to approve the deployment of changes, for example.

The operations supervisor has knowledge of regulations on the handling and storage of chemicals and ensures that they are taken into account during different stages of the change management process.

The role of other statutory responsible persons (e.g. supervisors of pressure equipment and electrical work) should also be described.

Requirement

Economic operators must have a documented procedure in place for temporary repairs of chemical pipelines and equipment.

Approved procedure

The documented procedure describes factors to be noted (e.g. risk assessment, technical requirements) and requires that the implementation of changes be documented (e.g. description of repairs, the material and methods used, the time and date of repairs, and responsible person). The economic operator had knowledge (e.g. separate list, information in the maintenance system) of all temporary repairs affecting process safety at the plant.

Requirement

Economic operators must have a procedure in place to identify temporary changes and assess risks.

Approved procedure

Temporary changes are identified as a separate type of changes in change management instructions. Risks associated with temporary changes are assessed. Different procedures may be defined for temporary changes compared to permanent changes.

Requirement

The impact of changes in the ownership structure or changes of ownership on process safety must be assessed and the measures required must be defined.

Approved procedure

The impact of changes of ownership on the process safety system is assessed and conclusions are documented.

Requirement

Economic operators’ written change management procedure must describe the procedures used to assess the impact of outsourced operations on process safety.

Approved procedure

The procedure covers the following:

- an assessment of whether the planned operations can be outsourced

- an assessment of the impact of outsourcing on the plant’s operations and process risks

- a straightforward method for the distribution of responsibilities

- an induction plan

- practices for information exchange between the economic operator and outsourced operations

Requirement

Economic operators must have a procedure in place to ensure process safety if the number of personnel or tasks change permanently or temporarily at their production plant.

Approved procedure

An economic operator has knowledge of the competence and the number of personnel required to carry out various tasks. During changes in personnel, it is ensured that competence or the number of personnel is not changed in such a way that the safe operation of the plant would be at risk.

Requirement

Economic operators must have a procedure in place to ensure the availability of information significant for process safety or plant operations during changes in the organisation and/or partners.

Approved procedure

An economic operator defines the information that must be available to it as part of the change management procedure. The requirement applies to outsourced operations and functions added to the plant’s operations as a result of changes.

Requirement

Economic operators must have a procedure in place to ensure that knowledge of plant-specific operating methods and special characteristics is passed on to employees transferred from another plant.

Approved procedure

The procedure includes induction regarding plant-specific operating methods and special characteristics.

Requirement

Economic operators must have a documented procedure in place for changes in statutory responsible persons and other persons significant for process safety.

Approved procedure

The system being used addresses changes in responsible persons, the verification of competence and the induction required.

CHANGE PLANNING AND RISK ASSESSMENT

Requirement

The change management process must include the assessment of process safety risks.

Approved procedure

The impact of changes on process safety is assessed as part of change management. Process safety risks are assessed taking into account the scope of changes. Different areas of safety in addition to process safety are addressed when assessing risks associated with changes (e.g. occupational, machine and food safety) to ensure that measures are in line with each other.

Requirement

Economic operators must define the risk assessment methods to be used in change management taking different types of changes into account.

Approved procedure

The risk assessment method is selected based on the type, duration and scope of changes. Different types of changes, including organisational, technical and raw material changes, are taken into account in the selection. The duration is considered based on whether a change is permanent or temporary.

Requirement

The documentation method for risk assessments must be defined in the change management procedure.

Approved procedure

A storage location has been defined for risk assessment documents and a responsible person has been designated for the saving process. The documents required include the risk assessment method used, risk assessment matrices and participants.

Requirement

Economic operators must have a procedure in place to address the requirements laid down in chemicals legislation in change planning (e.g. risk assessments, ATEX container and pipeline regulations, pressure equipment regulations, positioning of sites relative to other operations).

Approved procedure

As a rule, the operations supervisor is responsible for addressing regulations, but depending on the nature and scope of operations, requirements can be identified and fulfilled using various other parties.

Requirement

Chemical containers to be built as a result of changes must be designed in accordance with approved standards, or structural container designs must be approved by an inspection body. Containers must be built in accordance with designs, and it must be possible to demonstrate their compliance with requirements.

Approved procedure

According to the Tukes guide Handling and storage of hazardous chemicals (in Finnish) , all containers of hazardous chemicals of more than 5 m3 must be subject to inspections of structural designs and structures. Such inspections must be conducted by an inspection body approved by Tukes.

Tukes maintains a list of approved standards.

The compliance of containers with requirements must be demonstrated by a declaration of conformity. An example of a declaration of conformity is presented attached to the Tukes guide “Handling and storage of hazardous chemicals”.

Requirement

Chemical pipelines built during changes must be designed and built at least in accordance with level PED I. A declaration of conformity must be provided for chemical pipelines before the deployment of changes.

Approved procedure

The declaration of conformity is saved in the economic operator’s document management system.

Requirement

An acceptable duration must be determined for temporary changes as part of economic operators’ change management process.

Approved procedure

Temporary changes are closed during their determined duration, and temporary changes cannot become permanent without a new safety assessment.

Requirement

When making temporary repairs to pipelines affecting process safety or other equipment, economic operators must assess the applicability of the planned repairs based on a risk assessment.

Approved procedure

Chemicals, process conditions, the repair method to be used, the position of the repair site, and the monitoring of the condition of the temporary repair are addressed in the risk assessment.

Requirement

A responsible person must be appointed for the measures defined in the change management process who is responsible for the implementation of the measures.

Approved procedure

A responsible person is appointed in writing. The responsible person has the knowledge and opportunity required to carry out their tasks. The responsible person is appointed taking into account the practices to be followed when the responsible person is absent or replaced.

Requirement

Economic operators must describe the roles and responsibilities that are necessary for change management in writing.

Approved procedure

Instructions address the different stages of change management.

Requirement

Economic operators must define written criteria for the approval of changes of different sizes.

Approved procedure

An economic operator defines who approves changes based on roles (e.g. plant director, maintenance manager, operations supervisor) or individuals. Different approval criteria can be defined for changes of different levels (e.g. new production line vs. replacement/addition of a single valve). The approver is indicated in change documentation.

IMPLEMENTATION AND DEPLOYMENT OF CHANGES

Requirement

Economic operators must have a procedure in place to ensure a safe deployment. The procedure applied to changes must be defined as part of change planning.

Approved procedure

The applicable procedure depends on the scope of changes. The purpose of the procedure is to ensure that requirements for a safe deployment exist. A checklist or similar can be used.

Requirement

Economic operators must identify changes that require the chemicals supervisor’s approval and/or a review of terms and conditions set in a decision issued by Tukes before the deployment of changes.

Approved procedure

The operations supervisor issues a written permit for the safe deployment of changes related to the handling and storage of chemicals. The operations supervisor can authorise another person to approve the deployment.

If Tukes has set terms and conditions for changes in its decision, the economic operator must ensure their fulfilment in writing.

Requirement

Economic operators’ change management procedure must include the review and/or updating of documents affected by changes.

Approved procedure

The documents to be updated and/or reviewed are defined based on a change risk assessment. A person responsible for updates is designated.

Requirement

Economic operators must ensure that sufficient training regarding changes in chemicals and process safety is provided for their own personnel and other personnel in the area if required.

Approved procedure

The training required is defined during change planning. The plan presents the scope and target group of training.

Requirement

The documents affected by temporary changes must be defined in the change management procedure. Economic operators must ensure that the revised documents required during changes are available and that the personnel are aware of the changes throughout their duration.

Approved procedure

Changes in existing documentation are described in writing. Changes may concern a new revision of instructions or a temporary version of a PI diagram, depending on their nature. The economic operator ensures that temporarily changed documents can be clearly separated from other documents.

Requirement

When repairing chemical pipelines or equipment temporarily, the condition of the repairs must be monitored based on risks. Monitoring must be regular, and it must be documented.

Approved procedure

As part of risk assessments for temporary repairs in chemical pipelines, it is defined how and how frequently the condition of temporary repairs is monitored. The monitoring method is selected based on risks. Monitoring is documented (e.g. form, checklist, maintenance system).

Closing changes

Requirement

Economic operators must have a procedure in place to verify that changes and defined measures have been completed as planned.

Approved procedure

Measures defined in change management are monitored in writing. Measures are acknowledged as completed. Final revised versions of updated documents are available before closing changes. The economic operator states that all official requirements and the measures identified in the risk assessment related to changes have been fulfilled. Changes are closed in writing.

Requirement

Economic operators must have a procedure in place to ensure that temporary changes are returned to a safe state before closing them.

Approved procedure

An economic operator has a written monitoring procedure to ensure that arrangements related to temporary changes (process, equipment, etc.) have been returned to the state preceding the changes. Temporary documents related to temporary changes are removed from use.