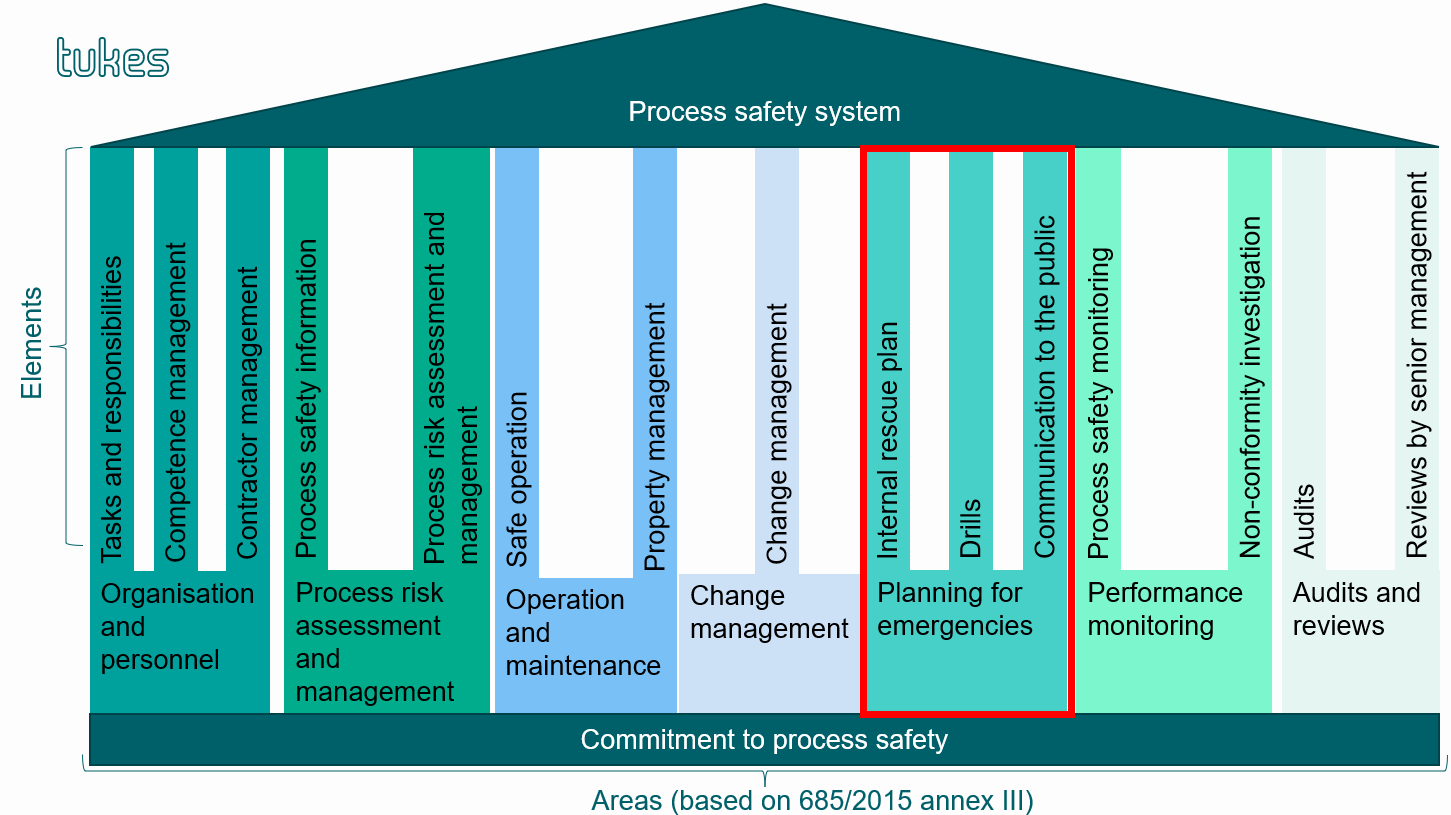

Planning for emergencies

‘Planning for emergencies’ is an area of the process safety system consisting of three elements: internal rescue plan, drills, and communication to the public. The goal of the area is to ensure a planned and practised readiness for accidents and emergencies, and provide the general public with sufficient information about accident risks associated with plants.

The internal rescue plan must be based on identified accident risks. It serves to plan what to do in the event of accidents and allocate sufficient resources for them. Accident response may also require cooperation to prevent the spread of accidents.

The activities defined in the internal rescue plan must be practised systematically. Drills must be based on identified accident risks. Development needs can be identified based on drills to further improve accident responses.

The obligation to communicate information to the public applies to facilities with a major accident prevention policy document and facilities obliged to provide a safety report. The latter facilities must distribute a public notice in the area which may be exposed to a potential accident. These types of facilities must keep such public notices always available in electronic or other format.

Internal rescue plan

Requirement

Economic operators must prepare an internal rescue plan regarding the measures required to prevent the impact of any chemical accidents, limit their consequences and prepare for remediation.

Approved procedure

A production plant has an internal rescue plan. Tukes has prepared instructions for the content of the internal rescue plan.

Requirement

The internal rescue plan must describe the preparations made at plants for accidents, and the personnel’s competence must match the planned measures.

Approved procedure

Preparations for accidents and the personnel’s related competence have been described in the internal rescue plan.

Requirement

The internal rescue plan must include instructions (for the rescue team, managers, all employees) for all types of accidents.

Approved procedure

The internal rescue plan covers leaks, fires, explosions, nearby accidents and natural phenomena.

Instructions for managers, specialists and communication cover the following:

- start-up and organisation of activities

- the command site and work areas

- contact with rescue teams

- cooperation with the rescue authorities and the provision of guidance

- communication responsibilities: nearby sites, media services, relatives, municipality, supervisory authorities

- start-up of after-care

Instructions for the rescue team cover the following:

- start-up and organisation of activities

- contact with managers and specialists

- protective equipment and its correct use

- measures to limit the consequences of an accident that can be taken by the operating team

- providing guidance for the rescue department

- stopping operations and meeting at the assembly point

Requirement

The internal rescue plan must present key results of the process risk assessment.

Approved procedure

The internal rescue plan presents a summary of the process risk assessment, including identified accident scenarios, their impact and related risk management measures.

The internal rescue plan can also refer to another maintained document (e.g. a safety report or a separate summary of risk assessments) in which these matters are presented. Employees have access to the information provided.

Requirement

The internal rescue plan must define the personnel resources required for accidents: management of activities, specialists, operating teams, communication.

Approved procedure

An economic operator assesses and plans the personnel resources with which it can carry out the measures defined in the internal rescue plan and provide the rescue department with sufficient expert help. The economic operator organises personnel resources so that the planned performance level can be achieved. Any irregular periods (regular and public holidays, etc.) are also taken into account in planning.

Requirement

The internal rescue plan must define the equipment, protectors and alarm systems required for accidents.

Approved procedure

The equipment to be used is selected based on risks so that it enables to carry out the rescue measures planned for the personnel in the internal rescue plan.

Requirement

The internal rescue plan must define the procedures used to warn the general public of accidents and communicate accidents.

Approved procedure

The procedure addresses support for official communication and the economic operator’s communication activities.

Requirement

The internal rescue plan must be prepared consulting the production plant’s personnel, including long-term subcontractors.

Approved procedure

Consultation procedures are documented as part of the internal rescue plan, an operating document or a safety report.

Requirement

The internal rescue plan must always be kept updated and reviewed every three years or when necessary. The updated internal rescue plan must be provided for the rescue department.

Approved procedure

The internal rescue plan is updated after changes in the production plant or rescue arrangements, based on findings made when updating risk assessments, after accidents or significant hazards, or after new information about measures to be taken to prevent major accidents has been obtained.

Requirement

The internal rescue plan must be addressed in change management and updated whenever there are changes that have an impact on rescue activities or accident risks.

Approved procedure

Updating practices for the rescue plan are addressed in change management procedures.

Drills

Requirement

Economic operators must hold voluntary drills for chemical accidents regularly for all individuals who work frequently in the specific area.

Approved procedure

Records of participants in drills is maintained. Drills are held regularly based on operations and process safety risks. In practice, this means drills at least every few years or several times a year.

Requirement

Economic operators must prepare an up-to-date plan for drills for chemical accidents.

Approved procedure

The plan includes drills related to chemical accidents. The plan describes the theme and schedule of each drill as well as participants.

The management of rescue activities is also addressed regarding drills defined in the internal rescue plan.

A responsible person or persons is/are designated for planning and holding drills defined in the internal rescue plan.

Requirement

Records of the progress and results of drills defined in the internal rescue plan must be maintained. Economic operators must have a procedure in place to develop internal rescue readiness based on findings made during rescue drills.

Approved procedure

The procedure covers the following:

- monitoring drills

- registering findings

- identifying development areas

- improving procedures and documents based on development areas, and monitoring the measures taken

- communication to the personnel

Requirement

Economic operators in a single plant area must cooperate to combat major accidents and prevent the spread of their consequences.

Approved procedure

Cooperation is based on joint preparation for accidents, including rescue drills.

Requirement

Training regarding key parts of the internal rescue plan and responses to emergencies must be provided for everyone working in the specific area, including subcontractors.

Approved procedure

The completion of training is recorded in a training register.

Communication to the public

Requirement

Public notices of facilities obliged to provide a major accident prevention policy document and facilities obliged to provide a safety report, or joint regional notices must include the information laid down in Annex VI to Government Decree.

Approved procedure

Information can be communicated to the public using a joint regional notice. Joint notices are subject to the same content requirements as plant-specific public notices.

Requirement

Facilities obliged to provide a major accident prevention policy document and facilities obliged to provide a safety report must keep their public notices available to the public in electronic and paper format.

Approved procedure

Public notices are available on the website of the company or rescue department.

Public notices are also available in format other than electronic (e.g. at the gate). The availability of public notices in format other than electronic also applies to facilities with a major accident prevention policy document.

Requirement

Public notices prepared by economic operators obliged to provide a safety report must be distributed in the area affected by a possible accident at the plant and to the municipality.

Approved procedure

Public notices of facilities obliged to provide a safety report are distributed to all properties in the area affected by possible accidents. Notices are distributed based on postal codes.

Requirement

Public notices of facilities obliged to provide a major accident prevention policy document and facilities obliged to provide a safety report must be kept up to date and updated at least every five years or after significant changes.

Approved procedure

Public notices of facilities obliged to provide a major accident prevention policy document and facilities obliged to provide a safety report must be kept up to date and updated at least every five years or after significant changes.